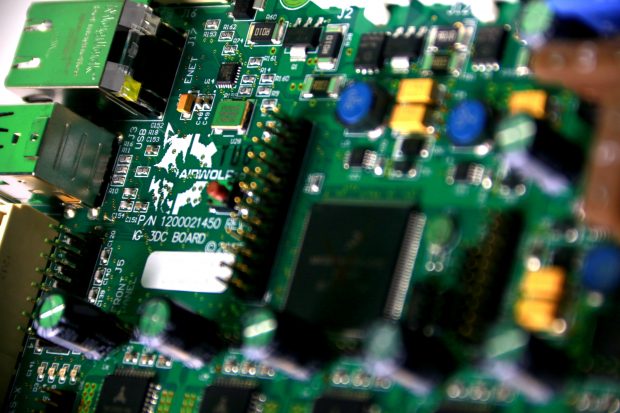

The EVO’s GENESIS microcontroller, Airwolf 3D says, was engineered from the ground up to support high-performance industrial manufacturing. Image courtesy of Airwolf 3D.

Latest News

January 31, 2018

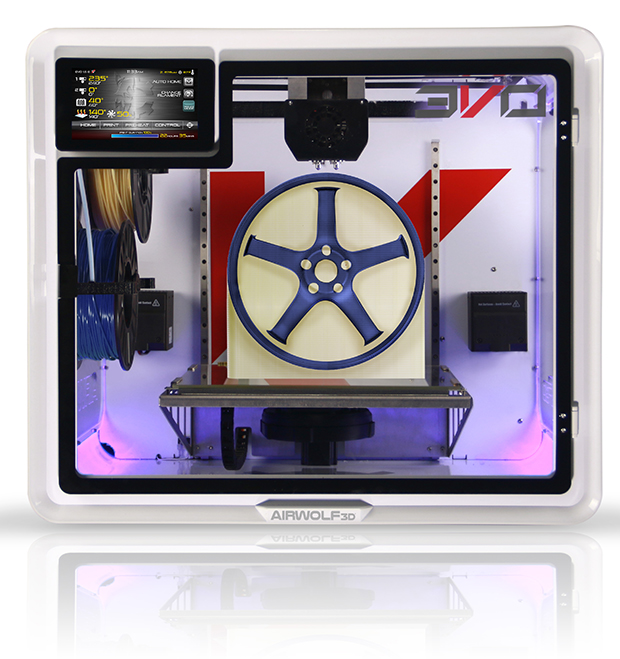

Airwolf 3D has released the EVO Additive Manufacturing Center, its fifth-generation additive manufacturing system. The desktop-sized EVO, says Airwolf 3D, features cutting-edge technology and advanced user-centered design that sets it apart from its past machines and elevates this 3D print system to a new class of industrial equipment.

Among the EVO’s user-centric functionality cited by Airwolf 3D is a feature called PartSave. Nicknamed the “Zombie Mode” by the company, this functionality remembers where a part was 3D printing, should the power fail. Once power is restored, PartSave resumes printing the part at where it left off.

Airwolf 3D describes its new desktop-sized EVO Additive Manufacturing Center as offering technologies and user-centered design features that elevate the system to a new class of industrial equipment. Image courtesy of Airwolf 3D.

Airwolf 3D describes its new desktop-sized EVO Additive Manufacturing Center as offering technologies and user-centered design features that elevate the system to a new class of industrial equipment. Image courtesy of Airwolf 3D.Similar to the new PartSave feature, the EVO has a new built-in FailSafe functionality. Intended for events such as jams or running out of filament, FailSafe enables users to position the printhead at the height where the print interruption occurred. Once the printhead is in position, FailSafe will then restore the print job, enabling the component to be completed.

Additionally, and in response to requests from schools and professionals for a “higher standard for a ‘healthy’ 3D printer,” the EVO has a HEPA (high-efficiency particulate air) and carbon filter air-purifying system for active containment of UFP (ultra-fine particle) and VOC (volatile organic compound) emissions.

Airwolf reports that the EVO is easy to control from its full-color 7-in. MATRIX touchscreen display. System and control capabilities accessible from the display include the PartSave functionality, material selection and an on-screen keyboard for writing and executing g-Code. The display reports operational data such as ambient temperature and print duration as well.

The EVO’s GENESIS microcontroller, Airwolf 3D says, was engineered from the ground up to support high-performance industrial manufacturing. Image courtesy of Airwolf 3D.

The EVO’s GENESIS microcontroller, Airwolf 3D says, was engineered from the ground up to support high-performance industrial manufacturing. Image courtesy of Airwolf 3D.The EVO’s internal intelligence is built around Airwolf 3D’s proprietary GENESIS microcontroller, which, the company says, was engineered from the ground up to support high-performance industrial manufacturing. It describes the GENESIS board as an “automotive-grade 32-bit redundant embedded controller that delivers two to three times higher speeds, more precision and greater control at ultra-high temperatures than any other desktop 3D manufacturing system on the market.”

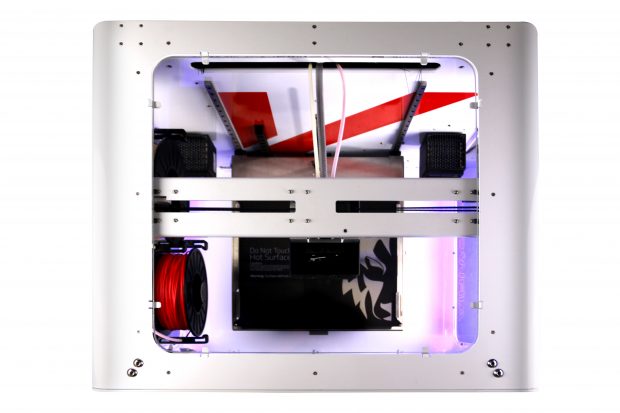

Among the EVO’s mechanical features are auto-leveling and calibration, high-torque cartridge-style planetary extrusion system, a stepper motor with an integrated stepper lead screw and CNC-style linear precision guides said to be maintenance free. The unitized, aluminum frame also houses a one-piece steel build plate, 1,000-watt power supply, automatic circuit breaker and a manufacturing vision system with ultra bright, dimmable focused LEDs.

A top-down view into the EVO Additive Manufacturing Center showing its CNC-style linear precision guides. Image courtesy of Airwolf 3D.

A top-down view into the EVO Additive Manufacturing Center showing its CNC-style linear precision guides. Image courtesy of Airwolf 3D.Print specifications include 12x12x11-in. (304.8x308.8x279.4-mm) build volume, 40-micron minimum layer height (200 microns or above recommended) and a 250 mm-per-second print speed. System dimensions are 40x30x29-in., (101.6x76.2x73.66-cm), and it weighs 115 pounds (52.16 kg).

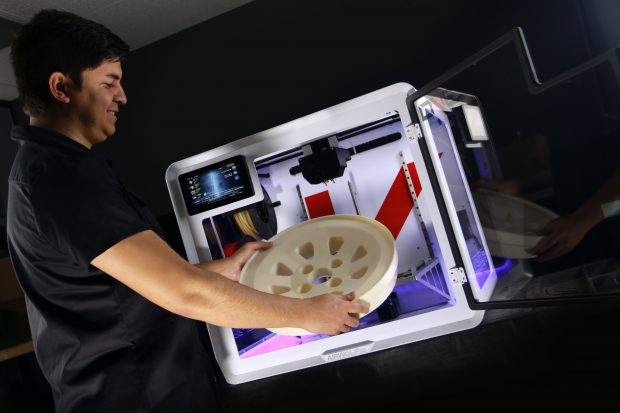

The EVO’s dual AX2 hot-end printheads, Airwolf 3D says, can handle materials with print temperatures up to 320ºC (608ºF). The system’s Tri-Heat Enclosed Build Environment provides “superior thermal management,” enabling users to print large parts out of high-temperature thermoplastic materials like ABS (acrylonitrile butadiene styrene), polycarbonate and polypropylene. In total, 40 different materials are available for use with the EVO, including carbon-fiber-reinforced nylon and the company’s water-soluble HydroFill support material.

“The EVO is completely new and it’s unlike anything out there,” explained Airwolf 3D Co-founder and CEO Erick Wolf, in a press statement. “The EVO is faster, stronger, and more accurate than any desktop 3D printer—it delivers a premium 3D manufacturing experience at less than half the cost of machines that offer equivalent performance. ... It’s a true desktop additive manufacturing center.”

The EVO Additive Manufacturing Center’s 12x12x11-in. build volume can be used to 3D print large parts. Forty different materials, including high-temperature thermoplastics, are available. Image courtesy of Airwolf 3D.

The EVO Additive Manufacturing Center’s 12x12x11-in. build volume can be used to 3D print large parts. Forty different materials, including high-temperature thermoplastics, are available. Image courtesy of Airwolf 3D.The EVO is available directly from the manufacturer and its authorized resellers. According to the Airwolf3D website, pricing for the EVO Additive Manufacturing Center starts at $7,995, including startup supplies and a year’s subscription to APEX Pro 2018 print control software. The targeted ship date is February 2018, according to the company.

For more info on the EVO Additive Manufacturing Center, click here.

Click here for details on available materials.

Learn about APEX 3D printing software.

See how the EVO’s sibling, the Axiom 3D printer, is used for custom-fitted shoes.

See why DE’s Editors selected the EVO Additive Manufacturing Center as their Pick of the Week.

Sources: Press materials received from the company and additional information gleaned from the company’s website.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Anthony J. Lockwood is Digital Engineering’s founding editor. He is now retired. Contact him via de-editors@digitaleng.news.

Follow DE