Latest News

January 23, 2013

How many times have you heard engineers and other manufacturing users say they just won’t give up on Excel? Despite the onslaught of new design tools, product data management systems, and engineering collaboration platforms, there remains a healthy fan club of users who cling to Microsoft Excel and related manual, paper-based processes as part of their regular workflows around engineering change orders, organizing parts lists, and creating work instructions, among other critical tasks.

In recognition of Excel’s enduring appeal, Lattice Technology has released Lattice3D Reporter v6, a software plug-in that lets manufacturing personnel—not just CAD-toting engineers—quickly and easily embed ultra-lightweight, but highly accurate, interactive versions of 3D CAD models and related parts information as part of any standard Microsoft Excel file. The 3D embedded information might be a bill of materials (or multiple bills of materials), work instructions, assembly animations, or 3D interactive snapshots, and using the free Lattice3D Reporter Viewer plug-in, users can review and interrogate the interactive 3D models and the associated information in the familiar Excel environment.

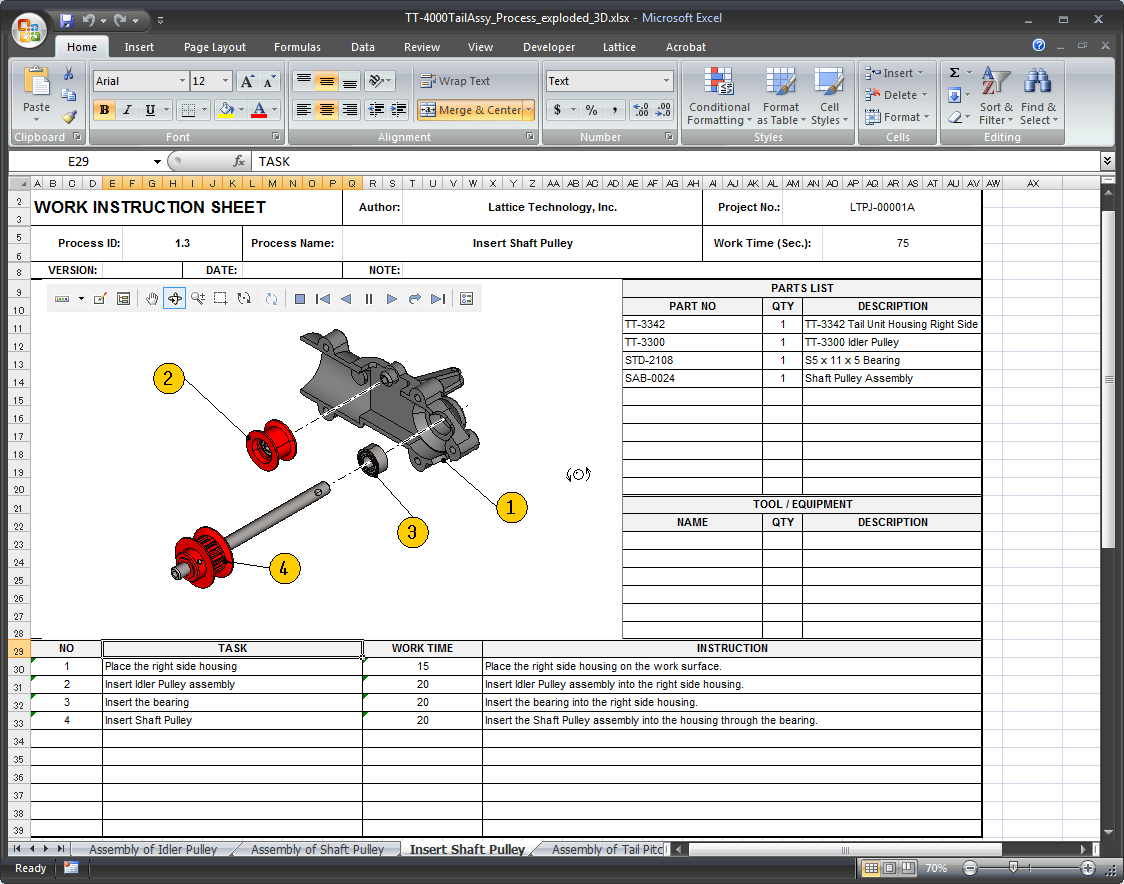

Work instructions are attached to the interactive geometry and the bill of materials. Image Courtesy of Lattice Technology Inc.

Work instructions are attached to the interactive geometry and the bill of materials. Image Courtesy of Lattice Technology Inc.Bill Barnes, general manager for Lattice Technology’s Americas and European divisions (the parent company is based in Japan), says the choice of integrating with Excel comes from the reality that the spreadsheet is a ubiquitous tool for sharing BOM and product-related information. “Excel is a tool everyone uses whether they are sharing BOM information or putting a sequence of parts together in an assembly document,” he explains.

Traditionally, people have used manual, paper-based methods for sharing this data, often collaborating using static documents. Lattice3D Reporter v6 and the Reporter Viewer establish associativity between the fully-functioning 3D models and a parts list, enabling users to identify parts much faster, perform cross sections to examine the model, and providing the ability to pan, rotate, and zoom on large and complex assemblies for the purpose of creating and exploring interactive parts lists or interactive assembly documents, Barnes says.

Lattice3D Reporter and its complementary Viewer ensure that when engineering data is updated and released, previously created spreadsheets are automatically updated, minimizing the possibility of costly errors. Image Courtesy of Lattice Technology Inc.

Lattice3D Reporter and its complementary Viewer ensure that when engineering data is updated and released, previously created spreadsheets are automatically updated, minimizing the possibility of costly errors. Image Courtesy of Lattice Technology Inc.“We’re bringing 3D and animation to a set of manufacturing engineers who are still using paper-based or electronic 2D documents,” he adds. “The interactive 3D models enable a greater understanding of assemblies and parts well before a manufacturing team embarks on building a prototype.”

Key to the ability to create the fully-functioning 3D models in Excel is Lattice Technology’s XVL technology, a lightweight 3D format that is used by companies like Toyota, Lockheed Martin, Boeing, and dozens of others to communicate product information through the manufacturing supply chain. XVL compresses data to an average of 0.5% its original size and also does so with high accuracy, Barnes says. That’s a characteristic that distinguishes it from other visualization and viewing technologies, particularly those offered by CAD and PLM vendors.

The toolset also enables 3D data to be readily integrated into existing ERP, PLM, and other IT systems. Lattice3D Reporter is an Excel plug-in which is available for purchase as a floating or node-locked license. The corresponding Lattice3D Reporter Viewer Excel plug-in is available as a free download from the Latttice Web site.

Below is a demonstration of how the technology works within Excel.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Beth Stackpole is a contributing editor to Digital Engineering. Send e-mail about this article to DE-Editors@digitaleng.news.

Follow DE