Sintavia Raises the Bar for Production-Level, 3D-Printed Parts

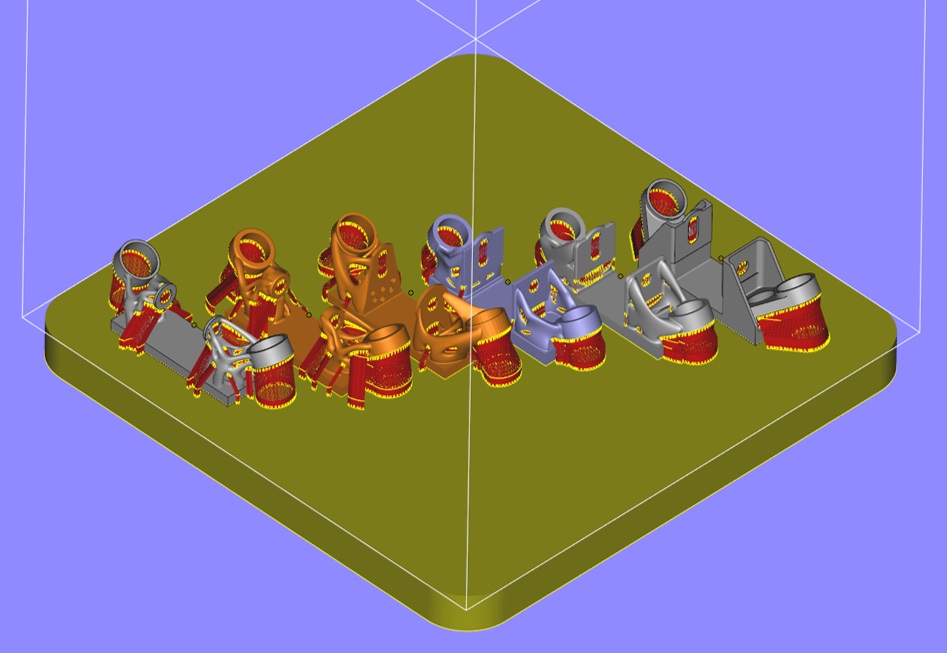

Sintavia Sample 3D-Printed metal parts on build plate (Image courtesy Sintavia)

Latest News

October 3, 2017

When the Sintavia production company came on my radar last winter, I was surprised by the depth of its capabilities. I thought, here’s an additive manufacturing (AM) service provider to watch — and how have I missed it? After digging into it some more, I was so impressed I found myself further wondering, will it fill the hole left by Morris Technologies?

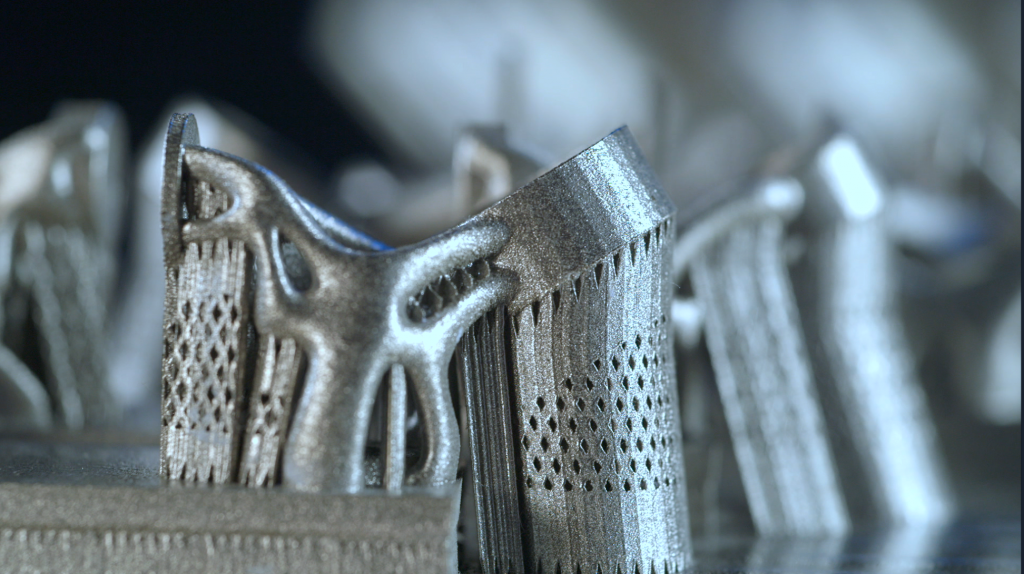

Mechanical load-testing a 3D-printed metal part, produced and tested at Sintavia. (Image courtesy Sintavia)

Mechanical load-testing a 3D-printed metal part, produced and tested at Sintavia. (Image courtesy Sintavia)In 2012 GE Aviation acquired Morris Technologies for in-house work, essentially shutting off that source of high-end metal AM parts procurement for everyone else. Yet in a classic case of “when one door closes, another one opens,” the timing was perfect for Sintavia founder and CEO Brian Neff to start offering similar services all thoroughly certified for aerospace, defense and other industrial customers. (The name Sintavia comes from “sintering” and “aviation.”) For customers who demand quality throughout the supply chain, Sintavia, based in Davie, FL is well on its way.

Accredited, Certified and Registered Throughout

“We’ve really taken a different approach to the technology,” explains Neff. “All of our backgrounds are in aerospace manufacturing and maintenance/repair/overhaul (MRO) services. We’ve taken that certification mentality to the technology, whereas a lot of our competitors are tooling or prototype shops that have added AM capabilities.” Metal parts laid out on build-plate, with support structures, for 3D printing. (Image courtesy Sintavia)

Metal parts laid out on build-plate, with support structures, for 3D printing. (Image courtesy Sintavia)In fact, notes Neff, Sintavia’s initial investments were not in AM machinery but in setting up powder and metallurgy laboratories. “The first machines we acquired were our scanning electron microscopes and inductively coupled plasma-optical emission spectrometry (ICP-OES) systems (for such tasks as verifying raw powder conformance and inspecting final-part microstructure),” he says. “That’s how we built up our competency, understanding the mechanical properties and metallography, then moving into the machines.”

He adds, “It’s helped us a lot, as we have five different OEMs (i.e., equipment from AM vendors Arcam, Concept Laser, EOS, SLM Solutions and TRUMPF) and they’re all a little bit different in how they print. Having on-site capabilities really helped us qualify rapidly and qualify well.”

Sintavia sample 3D-Printed metal parts on build plate. (Image courtesy Sintavia)

Sintavia sample 3D-Printed metal parts on build plate. (Image courtesy Sintavia)A Full Supply-Chain Provider

Newcomers to AM part production often see the job as simply requiring a service provider to take a 3D CAD file, ensure the design envelope will fit in the build volume of an AM system, and run it in a particular metal. Neff says it’s better to start with the requirements of the end part; for a customer to say, here’s a 3D drawing, here are the metals we’re most comfortable with – help us create the file or help us make it fit the criteria.Material-wise, Sintavia works primarily with titanium, nickel and aluminum, the traditional cast-metal materials, for customers in aerospace, engine design and space applications, respectively. He feels that list will expand over time. The company has previously worked with maraging steel for tooling, and has capabilities in-house for testing and mixing other powdered materials.

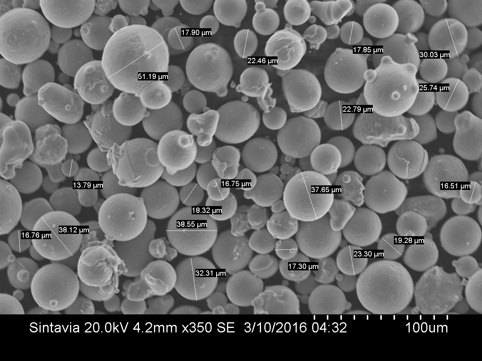

Scanning electron microscope image of raw powdered metal for 3D printing, inspected for consistency of granule dimensions. (Image courtesy Sintavia)

Scanning electron microscope image of raw powdered metal for 3D printing, inspected for consistency of granule dimensions. (Image courtesy Sintavia)“If you don’t have good certification for a part,” Neff points out, “it’s just an expensive paperweight. We really want to make sure you have good data – not just the way (a part) looks but also what it contains. The FAA is strict about what kind of data you need and that’s our pedigree; people in other industries like power and gas are amazed by the quality.”

Below are just some of the analyses, processes and tests for which Sintavia has equipment and expertise all under one roof:

- Powder characterization (size distribution, chemical composition, internal porosity, flow rate)

- Metallurgical testing (sample parts and final parts; metallographic examination per ASTM requirements, scanning electron microscopy, hardness testing—multiple standards, failure analysis testing)

- Mechanical testing (creep/stress rupture, tensile, fracture toughness, crack propagation, micro hardness, fatigue, with high temperature options)

- Post-processing (vacuum heat treatment furnace for annealing, hardening, precipitation strengthening, etc., hot isostatic press (HIP) for densification, wire EDM)

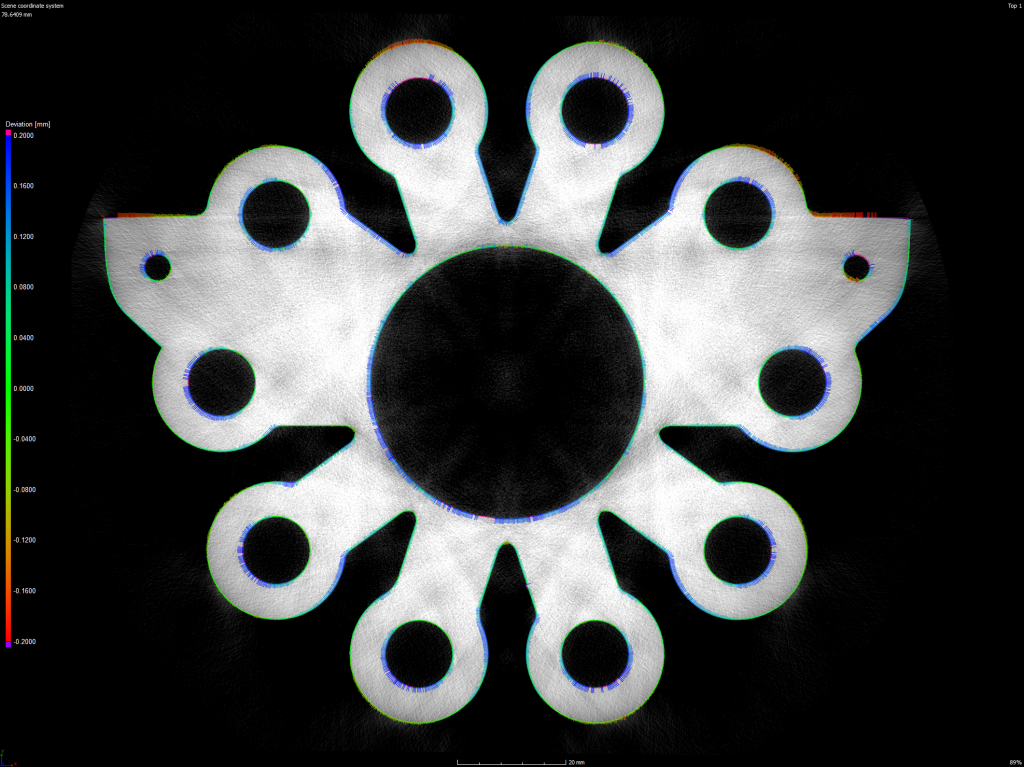

- Precision scanning and quality control (non-contact blue-light scanning and non-destructive CT testing)

CT scan performed by Sintavia on one of its metal additively manufactured parts — a fuel splitter — showing a fine, uniform level of density and internal passages that traditional contact and line of sight measuring systems cannot evaluate. (Image courtesy Sintavia)

CT scan performed by Sintavia on one of its metal additively manufactured parts — a fuel splitter — showing a fine, uniform level of density and internal passages that traditional contact and line of sight measuring systems cannot evaluate. (Image courtesy Sintavia)Vertically Integrated AM Production Services

Sintavia is already expanding its facilities to handle the increasing customer workload, with goals of adding 35 more AM systems plus larger furnaces and HIP equipment by 2020. Already, says Neff, “Our digital advanced manufacturing facility (opening in Hollywood FL in Q3 2018) will continue to replicate the vertical integration we have in our existing shop but with more of a flow for larger scale production. What we have now is not big enough for what we need to do.” They also plan to replicate this factory system in other locations around the country, including the upper Midwest, Southwest and Northwest.Sintavia believes the Tier One suppliers of tomorrow are not the Tier Ones of today, and that it is already on a path to join the former group: “The only way to do that is to build a good factory system and replicate it near your customers.”

NOTE: Sintavia offers videos with a wealth of fine detail about design optimization, powder testing, post-processing and mechanical testing and analysis. See Optimized Turbine Bracket case study and Sintavia Testing and Analysis of Aerospace Parts Made by Additive Manufacturing.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Pamela Waterman worked as Digital Engineering’s contributing editor for two decades. Contact her via .(JavaScript must be enabled to view this email address).

Follow DE