Stratasys Advancing AM With New Solutions for Factory Floor

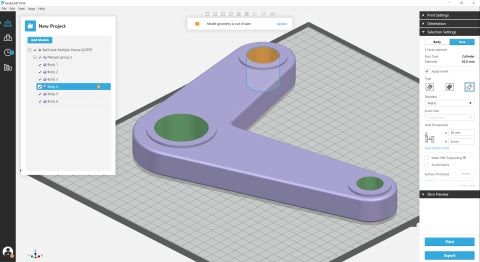

Combining the GrabCAD Print interface with the Stratasys Insight software, Jigs and Fixtures for GrabCAD Print automates previously complex part preparation tasks. Image courtesy of Stratasys.

Rapid Prototyping and Manufacturing Services News

Rapid Prototyping and Manufacturing Services Resources

Latest News

April 24, 2018

Stratasys has unveiled a range of new solutions for additive manufacturing on the factory floor, announced during RAPID+TCT 2018 in Fort Worth, TX.

The new F900 Production 3D Printer is factory-floor ready with MTConnect interface and composite material compatibility. Image courtesy of Stratasys.

The new F900 Production 3D Printer is factory-floor ready with MTConnect interface and composite material compatibility. Image courtesy of Stratasys.Announcements include an expanded number of 3D printers compatible with carbon fiber composite material, including the new F900 Production 3D Printer, the third generation of the company’s flagship FDM system. Features include an MTConnect-ready interface with production-ready accuracy and repeatability, the company reports.

The F900 is built on the Fortus 900mc platform and is available in a new series of three solutions: the F900, the F900 AICS (Aircraft Interiors Certification Solution),and the F900 PRO.

The following two versions of the F900 extend the platform into a series of specialized products supported by high repeatability:

Stratasys F900 Aircraft Interiors Certification Solution (AICS), which delivers traceability required for flight-worthy parts; and

Stratasys F900 PRO, a production-grade system, ready to produce parts with high fused deposition modeling repeatability and performance in ULTEM 9085 resin.

Owners of existing Fortus 900mc systems can upgrade to any of the three current F900 systems.

In addition to Nylon 12 CF being offered on the Fortus 900 and 450 systems, Stratasys Direct Manufacturing is also now offering parts built with FDM Nylon 12CF, ideal for functional prototypes and production parts in high-requirement applications, the company reports.

Stratasys additionally is offering this material on a specialized Fortus 380 and now has a family of 3D printers in a range of price points that can build with Carbon Fiber Nylon 12. Stratasys expects the Fortus 380 CF to ship in the second or third quarter of this year.

In related news, the company highlights its enhanced Stratasys J750 3D Printer alongside the new Stratasys J735 3D Printer, which enables designers and engineers to build realistic prototypes with streamlined design-to-prototype workflows. Offering in excess of 500,000 color combinations via a new vivid color package, color matching and advanced clear with texture functionality, the PolyJet-driven systems create prototypes that are intended to look, feel and operate like finished products, the company reports. Eliminating costly requirements for painting, assembly, or post-processing, both systems shrink prototype cycles by producing parts that are consistent.

Stratasys vivid colors, color matching, and clear with texture functionality is well-suited to meet the 3D printed prototype demands of auto manufacturers. Image courtesy of Stratasys.

Stratasys vivid colors, color matching, and clear with texture functionality is well-suited to meet the 3D printed prototype demands of auto manufacturers. Image courtesy of Stratasys.Enhanced GrabCAD Print software, now also available for the Connex3 3D Printer, further improves workflows and functional prototyping for parts requiring ABS-level plastic simulation and tear-resistant rubber-like parts.

The newly advanced J750 and J735 PolyJet 3D Printers simulate parts with full color and textures, ranging from rigid to flexible, transparent to opaque. Additionally, two new materials, VeroYellowV and VeroMagentaV, deliver enhanced red/orange/yellow colors with next stage translucency. These advanced colors are available both on the J750 and J735 3D Printers - and now the Connex3 3D Printer.

Taking the capabilities of the Stratasys J750 and J735 3D Printers and the Connex3 one step further is GrabCAD Print, allowing designers to 3D print directly from native CAD formats and saving time typically used to convert and fix STL files, the company reports. The software also has new ability to 3D print VRML files to power more realistic textures, images and graphics on-part.

In more news from Stratasys, the company is seeking beta customers for its new software designed to improve the Stratasys Additive Manufacturing solution for the production of jigs, fixtures and other manufacturing tooling.

This new software component—called Jigs and Fixtures for GrabCAD Print—simplifies and automates print preparation for rapid tooling applications.

The new software will help industry streamline operations and improve efficiency for jig and fixture creation. Offered through GrabCAD Print, the software embeds application expertise, automates several complicated and time-consuming processing steps, and eliminates the need for multiple programs within the workflow.

Jigs and Fixtures for GrabCAD Print expands upon the capabilities offered in Stratasys Insight to streamline the toolpath planning process; increasing ease of use, reducing time and costs to create jig and fixture parts, and maximizing the value for Stratasys’ Additive Manufacturing solutions.

By accepting native CAD designs, the part’s original design intent is maintained. This eliminates the need for users to convert their CAD design to an STL file, which can result in key information being lost during translation. With Jigs and Fixtures for GrabCAD Print, Stratasys offers tooling designers and manufacturing engineers a streamlined design-to-part workflow and a user-friendly path between tooling CAD design and additive manufacturing.

Combining the GrabCAD Print interface with the Stratasys Insight software, Jigs and Fixtures for GrabCAD Print automates previously complex part preparation tasks. Image courtesy of Stratasys.

Combining the GrabCAD Print interface with the Stratasys Insight software, Jigs and Fixtures for GrabCAD Print automates previously complex part preparation tasks. Image courtesy of Stratasys.The Jigs and Fixtures for GrabCAD Print software is targeted to manufacturing engineers, tooling designers, and production managers, as well as service bureau programmers, executives, and owners.

Those using Stratasys 3D Printers for jig and fixture or manufacturing aids production and would like to participate in the beta software program may contact Stratasys here.

To learn more, stop by its booth at RAPID+TCT 2018 (Booth #1104) or visit Stratasys.

Sources: Press materials received from the company.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

DE’s editors contribute news and new product announcements to Digital Engineering.

Press releases may be sent to them via DE-Editors@digitaleng.news.