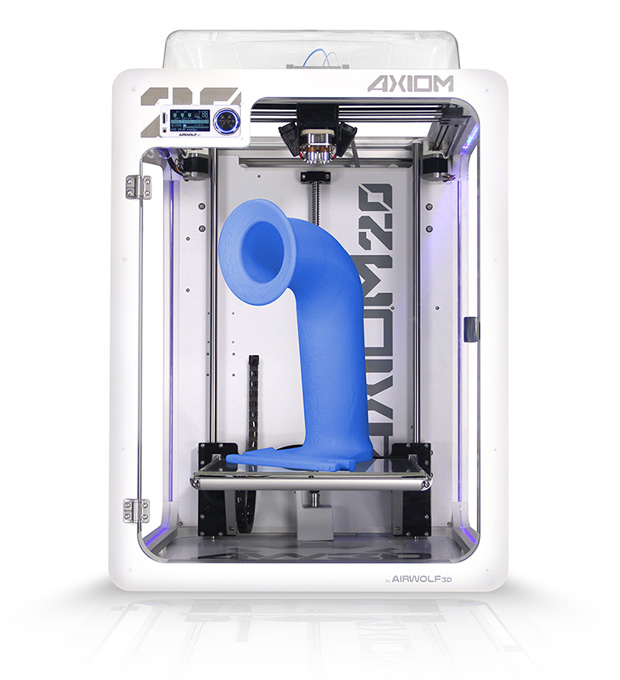

The AXIOM 20 dual-drive desktop 3D printer has a 12.5x12x20 in. build chamber that allows designers and engineers to fabricate large full-density parts. Image courtesy of Airwolf 3D.

Latest News

November 9, 2016

Airwolf 3D Printers has introduced the AXIOM 20, an industrial-use desktop 3D printer that can be used to make full-size prototypes and molds as well as for production runs. The AXIOM 20, says Airwolf 3D Printers, offers “a towering 20-inch Z-axis,” a fully enclosed 12.5x12x20 in. build chamber and the ability to print high-density parts.

The AXIOM 20 system unit features a modular, upgradable design. It's built with industrial-strength steel and aluminum construction, and it measures 25x23x35 in. (635x584x889 mm). The system can operate for 30 or more hours at a time, adds the California-based company.

The AXIOM 20 dual-drive desktop 3D printer has a 12.5x12x20 in. build chamber that allows designers and engineers to fabricate large full-density parts. Image courtesy of Airwolf 3D.

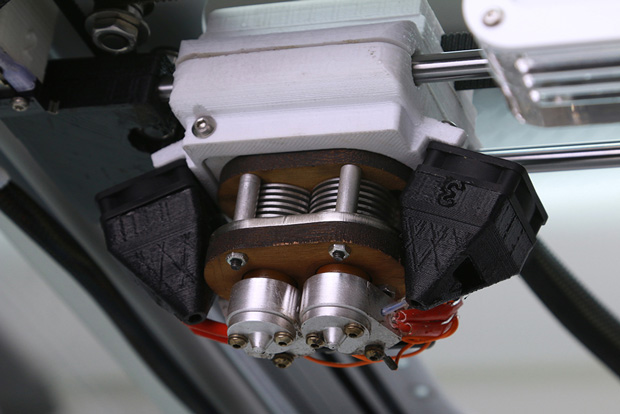

The AXIOM 20 dual-drive desktop 3D printer has a 12.5x12x20 in. build chamber that allows designers and engineers to fabricate large full-density parts. Image courtesy of Airwolf 3D.Major system components include direct-drive dual extruders with independently controlled hot ends, a core XY motion control system and an “easy feed” filament system. The extruder's hot ends can reach independently controlled temperatures of 599°F (315°C) and enable designers to 3D print in two colors or with two different materials. The extrusion nozzles are interchangeable (from 0.35 to 0.80 mm) and engineered to resist clogging.

The hot ends on the AXIOM's dual extruder can reach independently controlled temperatures of 599°F (315°C). Image courtesy of Airwolf 3D.

The hot ends on the AXIOM's dual extruder can reach independently controlled temperatures of 599°F (315°C). Image courtesy of Airwolf 3D.The AXIOM 20 calibrates its print bed automatically, which ensures optimal bed leveling and head spacing before beginning every print, says Airwolf 3D Printers. Its print speed is 9.85 in. per second (250 mm/s). Minimum layer height is 40 microns (200 microns or higher recommended). With the AXIOM 20 designers and engineers can 3D print parts, prototypes and production runs in more than 40 different materials, including thermoplastic elastomers, thermoplastic polyurethane, flexible nylons and rubber-based materials as well as high-temperature, industrial-grade polycarbonate and polypropylene.

The AXIOM 20's dual extruders enable designers to 3D print rapid prototypes and functional products in two colors or with two different materials. Image courtesy of Airwolf 3D.

The AXIOM 20's dual extruders enable designers to 3D print rapid prototypes and functional products in two colors or with two different materials. Image courtesy of Airwolf 3D.“One of the biggest challenges with designing a high-performance 3D printer of this size was getting the Z-axis to work correctly over 20 inches of travel with 20-30 lbs. sitting on it,” said Erick Wolf, Airwolf 3D Printers co-founder and lead designer, in a press statement. “We redesigned the bed bracket system and switched from plastic and polycarbonate parts to all aluminum and steel components. Plus, the Z-axis now has a precision ball screw to provide high repeatability, zero backlash and extreme precision.”

The AXIOM 20 also comes with connections for Ethernet, Micro SD (secure digital), USB and Wi-Fi. APEX 3D-printing software, developed exclusively for Airwolf 3D printers, is available as a complimentary download. APEX comes preconfigured with print profiles for major materials, and the material profiles are fully optimized for all models of Airwolf 3D printers, according to the company.

With the AXIOM 20 designers and engineers can 3D print large parts, prototypes and even production runs in more than 40 different materials. Image courtesy of Airwolf 3D.

With the AXIOM 20 designers and engineers can 3D print large parts, prototypes and even production runs in more than 40 different materials. Image courtesy of Airwolf 3D.All AXIOM Dual 3D printers are made to order, according to the company. A suggested AXIOM 20 configuration costs $9,995, which includes a one-year parts and labor warranty, starter materials and unlimited technical support for six months. Leasing programs are available. For more details on the AXIOM 20, visit Airwolf 3D Printers.

Click here to load more abut the material options available for the AXIOM 20.

Download the AXIOM 20 spec sheet.

Go here to learn more about APEX 3D-printing software.

Learn more about Airwolf 3D Printers here.

See why DE's editors selected the AXIOM 20 desktop 3D printer as their Pick of the Week.

Sources: Press materials received from the company and additional information gleaned from the company's website.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

DE’s editors contribute news and new product announcements to Digital Engineering.

Press releases may be sent to them via DE-Editors@digitaleng.news.