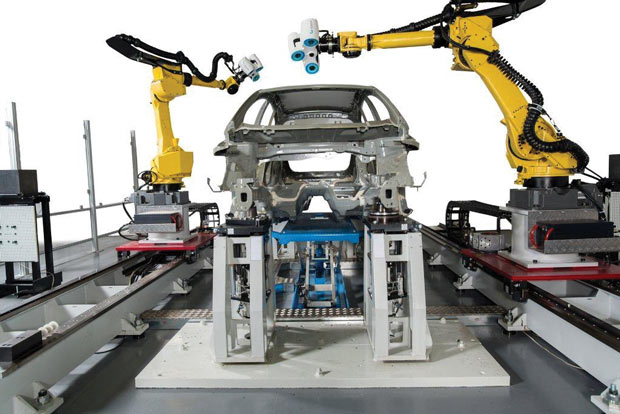

The 360° Smart Inline Measurement Solutions (360° SIMS) from Hexagon Manufacturing Intelligence is a family of measurement solutions designed for automotive production lines. Image courtesy of Hexagon Manufacturing Intelligence.

March 1, 2016

The 360° Smart Inline Measurement Solutions (360° SIMS) from Hexagon Manufacturing Intelligence is a family of measurement solutions designed for automotive production lines.

The 360° Smart Inline Measurement Solutions (360° SIMS) from Hexagon Manufacturing Intelligence is a family of measurement solutions designed for automotive production lines.Image courtesy of Hexagon Manufacturing Intelligence.

Metrology service providers will do everything from recalibrating your calipers to helping set up automated aircraft assembly systems. They’ll measure anything from tiny screws and stents to entire buildings.

“There are so many different [reasons why] someone would need metrology services,” says Cali Schwartzly, marketing and business development manager at ECM Global Measurement Solutions. “We have customers that continuously ship batches of small parts to us because they need our CMM (coordinate measuring machine) and our lab to take the measurements. Or we can do months of automated airplane assembly integration, on-site, using laser trackers. We might come in, show them what needs to be done and do the work for them. In the long term, they might end up purchasing a piece of equipment and getting engineers trained to use it.”

One thing potential metrology clients do have in common is a lack of time. “Usually, by the time someone [realizes that] they need contract measurement services, they’re already behind,” says Schwartzly. “They’ve tried every resource. They’ve been waiting for budget for a piece of equipment, or maybe they have the equipment but they didn’t really think about the time it takes to hire and train an engineer to actually work it. Finally, they get so back-logged that they call us, and say: ‘Can you come tomorrow?’”

That might not be possible. Providing contract metrology services can be more complicated than selling metrology equipment. “With some high-profile companies, there are so many hoops to jump through before they’ll even let you into their facility to do any work,” Schwartzly says.

Faster, Better, Faster

Manufacturers need more precise, and faster measurement than ever before, says Keith Gudeman, business development manager at Hexagon Manufacturing Intelligence. Among other reasons, today’s assembly lines are often producing more intricate products at much higher production rates.

“Think of a flip phone 10 years ago,” says Gudeman. “There were one or two measurements, max, made on the little piece of glass.” But, while the glass in a flip phone serves as a simple protective shield for the screen behind it, the glass in a smartphone is an integral part of the phone’s functionality and can require 20 or more measurements.

“They’re checking for flatness,” says Gudeman. “They’re checking orientation once assembled. They’re checking thickness in a number of areas. If you have inconsistent glass flatness and thickness, it’s not going to function correctly.”

All of these measurements can be made in-line, for every piece of glass on every phone, and at astonishing tolerances. “They’re holding components to micron levels, not millimeter levels,” says Gudeman. This is clearly not a job for technicians with calipers. Fortunately, there are newer technologies available, such as Hexagon’s vision CMM systems. “It’s completely automated,” says Gudeman. “Parts are presented, all the measurements are taken, and the parts are removed. It takes place as part of the assembly process.”

Industrial Computerized Tomography

Glass parts notwithstanding, high-speed vision CMM is really only good at measuring the outside of parts. If you need to look inside, consider industrial CT—computerized tomography. Like the more familiar medical CT, industrial CT scanning works by taking a series of X-ray images from different angles and building a 3D model from the resulting data.

CT can solve a host of difficult measurement problems. You can accurately scan a tiny fly’s eye, or a delicate rose petal, but CT’s primary benefit is the ability to non-destructively see inside things.

“You have full internal and external scanning capabilities,” says Andrew Good, quality manager, JG&A Metrology Center, “and you don’t have to section the part like you would with CMM, white light or lasers.”

Those technologies are strictly line-of-site and require you to slice the object up (to section it) in order to inspect the insides. That’s an especially big problem with really high-dollar parts and makes it impossible to inspect parts before actually using them. JG&A does a lot of work for aerospace and defense companies that require each part to be certified, and you can’t slice parts up and then bolt them onto an airplane.

CT scans provide density information in addition to XYZ data to help distinguish between materials. “With something as simple as a sand casting,” says Good, “you can see if there’s any sand left inside the internal passages.”

CT is a relatively new technology, at least it North America. CT scanning is expensive because the equipment is expensive and it’s far from portable. But if you need to measure the insides of a part without chopping it open, it’s really your only option.

Mobility and Metrology

CT scanners are amazing but they’re big and bulky; and there’s something to be said for portability. “We primarily use portable metrology equipment,” says Mitch Fields, co-owner at TriMet. That equipment includes articulated arms, laser trackers and laser scanners.

“You can bring the equipment right up to the machine bed,” says Fields. “The other day, we were at a lock and dam to measure gears that were binding. We were able to do that right on the spot. Obviously, there’s no way you could take a stationary CMM into that area.”

Laser scanning is becoming TriMet’s forte. “We [might be] commissioned to go in and measure an assembly line tool while the workers are at lunch,” Fields says. “We have 30 minutes to get in, scan everything and get out.”

Companies like Heidenhain Corp. provide inspection and gauging products for both end-users and original equipment manufacturers. Image courtesy of Heidenhain.

Companies like Heidenhain Corp. provide inspection and gauging products for both end-users and original equipment manufacturers. Image courtesy of Heidenhain.Laser scanning isn’t quite as accurate, but it’s getting better all the time, says Fields. “The accuracy delta between probing and scanning used to be quite large. Now they’re virtually the same,” he says. “Probing is still more accurate, especially with a stationary CMM, but the difference now is down to a couple ten-thousandths of an inch.”

And scanning is more thorough. “If we probed everything and we forgot something we’re out of luck, because the production line is back up,” Fields says. “But if we scan, we can always extract all the dimensions we want. It’s kind of foolproof in that sense.”

Expanding Everywhere

Many metrology service providers are experiencing growth. Some firms are just receiving more calipers and multi-meters to calibrate, others are expanding in whole new directions. TriMet is doing ever more laser scanning. JG&A reports an explosion in demand for structured light scanning. ECM is measuring larger and larger structures, from pipelines and factory buildings. Hexagon Manufacturing Intelligence is growing its focus and expertise to offer integrated measurement solutions.

“We do everything from medical stents to engine collars for jet engines,” says JG&A’s Good. “You’ll have people asking you to scan statues, or dental implants or screws. It’s a weird, diverse industry.”

Some companies’ offerings are overwhelming, seeming to provide every conceivable service, including several you might not recognize. “Clearly,” says ECM’s Schwartzly, “there’s a disconnect between what customers think they want and what we know they need. It’s all about the terminology. We think we provide contract measurement services or laser tracker services, but customers might type in ‘aircraft measurements.’ If [your search] doesn’t include specific industry terms, it’s going to be hard to find someone who does what you need.” Be sure to include any required ISO, CMS or NADCAP certifications in your search.

If you already have metrology hardware and software on site, check with the vendor or manufacturer because they’ll often be able to recommend metrology firms to work with you.

More Info

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

Mark ClarksonContributing Editor Mark Clarkson is Digital Engineering’s expert in visualization, computer animation, and graphics. His newest book is Photoshop Elements by Example. Visit him on the web at MarkClarkson.com or send e-mail about this article to DE-Editors@digitaleng.news.

Follow DE