Automating and digitizing engineering change orders can connect data and provide time savings. Image courtesy of Omnify.

Latest News

April 1, 2016

Automating and digitizing engineering change orders can connect data and provide time savings. Image courtesy of Omnify.

Automating and digitizing engineering change orders can connect data and provide time savings. Image courtesy of Omnify.Managing engineering change orders (ECOs) has become more important and complex as more products incorporate complex electronics or Internet of Things (IoT) functionality. Even industrial goods that previously had a relatively simple bill of materials (BOM) or document sets now face much more complicated quality and compliance issues when it comes to engineering changes.

“Change management is a critical and vital part of many businesses, because they have changes coming from a variety of places, including internal staff, manufacturing, sales, or from external customers and suppliers,” says Scott Lamond, vice president of Marketing and Business Development at Synergis Software. “How do you streamline a process that is often manual, paper-based, or phone- or e-mail-based, so that it’s more efficient and costs less, and takes less time to complete?”

Effectively managing the processing of the ECO, tracking changes and approvals, and updating documents, drawings, and data stores across multiple systems is simply too complex to manage using spreadsheets. In the past, these tasks were spread across multiple systems (i.e., schematics in the CAD solution and parts lists in Microsoft Excel). That led to time-consuming manual processes and errors.

“You might be able to use spreadsheets for simple products and pull that off for a while,” says Steve Chalgren, chief strategy officer and executive vice president of Product Management at Arena Solutions. Arena specializes in the high-tech electronics space, where engineers have to manage complex BOMs and multiple change orders. “In the electronics industry, there can easily be hundreds of different ECOs released between two versions of the same product. You have a high rate of change, multiple products and multiple people involved in the product process for revising the design, electrical components and firmware. If any one of those people has the wrong version of the materials, that could stop production or cause a product failure in the field.”

Without an automated solution, manual processes cause delays in change order approvals and ultimately delay product releases. “If you don’t have a system in place, then you have print outs and you’re walking a physical folder from person to person to do sign offs,” says Chuck Cimalore, CTO and president of Omnify Software. “In our system, you now have inherently parallel processes so multiple people are viewing and signing off, and suggesting additional changes in one system.”

There are a number of different types of solutions that can help manage and automate these processes: product lifecycle management (PLM), document management, electronic content management, product data management (PDM), E-CAE, etc. They all trade in information management, and can help get a handle on files and unstructured content.

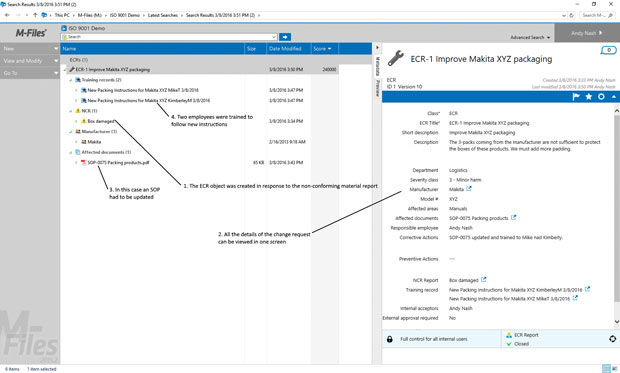

“We provide different ways to optimize processes associated with that content,” says Greg Milliken, vice president of Marketing at M-Files. “Not only the workflows and processes, but also ensuring that changes are not getting overwritten without proper authorizations.”

M-Files’ enterprise information management system gives greater transparency to any changes throughout the workflow. Image courtesy of M-Files.

M-Files’ enterprise information management system gives greater transparency to any changes throughout the workflow. Image courtesy of M-Files.These solutions use central databases to coordinate the documents and files associated with a project — as well as all of the data. That’s important because not all of the information related to a specific project is necessarily housed in a document, per se.

Streamlining the ECO Process

ECOs allow organizations to adjust or debug designs while providing an audit trail of when those changes are made. They typically include technical information about the changes (parts, components, drawings, etc.) as well as explanations, instructions, approvals and lists of departments or staff affected by the change.

Electronic ECOs be linked to drawings, spreadsheets, BOMs and other related files. “Relationships are created between the form and all of the associated documents,” Lamond says. “You can find those files via intelligent search features, collect them, and link them to the changes.”

Change orders can be automatically routed to make processes more efficient, and can be accompanied by automated email notifications. The solutions can also be configured to trigger other processes in other solutions. Change approvals can also be accomplished via electronic signatures.

The entire process is also more efficient because there is no longer any paper or printing to manage — change orders can be more quickly created and linked to the necessary files.

“This is really about creating a process that people can follow and will consistently follow in an efficient, ongoing way,” Milliken says.

In Synergis Adept, for example, users can set up automated change order processes in the solution. “You also have multi-user markup capabilities, so people can collaborate on these changes as they are routed through the approval process,” Lamond says.

In Omnify, as a new element (like a drawing) is added, the system creates a live element that all stakeholders are aware of. As changes are made, a red line environment is automatically established so everyone can see the changes and note the differences between the original and new versions. “The system assigns workflows behind all of these processes, based on each person having their own set of rules and businesses role associated with access,” Cimalore says.

Once all approvals have been signed in the system, all of the product records can be updated, including drawings and BOMs. New revisions are reflected in other systems (CAD, Excel documents, etc.), and instructions can be issued to the ERP (enterprise resource planning) system for manufacturing.

Making this work requires more than simple file management. The documents and files have to be tied to other information that exists in multiple systems. Companies have to know who the customer is, what purchasing information the manufacturing group needs to complete the project, which vendors are involved, etc. “There is a lot of crucial information that exists within those systems that allow us to more efficiently mange the process and allow people to discover documents,” Milliken says. “That requires metadata-based information management.”

According to Milliken, traditional folder-based management is ill-suited to this type of collaborative work because the information in the folders has to appear in multiple places at the same time. “An invoice might be important to me in purchasing, but somebody else in a different role in manufacturing might have an interest in it as well,” Milliken says. “You have to classify information by what it is, not where it’s stored.”

“Living” Document Management

The key benefit of applying PLM or document management technology to the ECO process is that the accompanying files (BOMs, drawings, etc.) can evolve right along with the details of the change order in ways that are accessible and visible to all interested parties.

“In contrast to a static Excel spreadsheet, the solution creates a living, breathing document that continues to tie to the product record,” says Kent Killmer, vice president of Marketing at Arena Solutions. “We have an item master and a relational dataset holding all of this together, which the BOM references. You can ‘go back in time’ to see changes, which is fundamental for liability purposes or warranty work.”

Transparency is improved. As engineers collaborate, changes are documented simultaneously across all departments and all related data sources and documents reflect the changes. Any modifications can be compared to previous versions, and the author of the changes (as well as all approvals) can be tracked.

This also makes it easier for different engineering disciplines to work together more efficiently. Rather than a sequential process, in which a change order passes from one group to another to evaluate the repercussions of a change, everyone sees the information at the same time and can collaboratively address any potential unintended consequences or problems.

“You can suggest changes to the software, the electrical systems, or to the hardware, and everyone is looking at it as a whole,” Cimalore says. “If you make a change in one area, it affects other disciplines. All of those things are dependent on everyone being able to see the full effect of the product change. Once you have a unified system, you get full collaboration; everybody can see what is going on.”

These solutions also document why changes were made. “That history of information and interactions are easily discoverable by key members of the team when someone needs to assess a change order or evaluate costs,” Milliken says.

In highly regulated industries, the change order process may need to stand up to close scrutiny and auditing for compliance. Notifications can be put in place so that the right people are automatically alerted when documents or projects have passed important milestones, or are in danger of missing important deadlines.

“As the project itself is advancing, you track and log access and revisions and version management based on those milestone reviews,” Milliken says. “Not only are you assuring manufacturing that they are dealing with the right version of the product, you are also building the foundation upon which you can show you are compliant with various regulations and quality standards.”

These solutions also make it possible to grant role-based access to stakeholders in different companies (customers or suppliers, for example), so that information can be shared or changes approved without requiring the physical shipment of documents or an in-person meeting.

In the case of M-Files, for example, those rights and roles can change dynamically. “If a change order needs to be reviewed by smaller groups of people, once it is reviewed and approved the rights to the document can change,” Milliken says. “That reveals the document to more people.”

“Each person has their own set of permissions that determine what they can access, and that can be done on a project level,” Cimalore says. “Third-party providers can get access without having to do anything on their end other than click a hyperlink.”

Arena provides two different ways to grant access to outside stakeholders. They can log into Arena and be granted object-by-object access based on their user privileges; or they use the Arena Exchange product to provide a snapshot of data. The latter provides a collaboration pane that lets a supplier or customer grant access to multiple people within the organization to collaborate in real time and share files.

“When you go to make a product, there are hundreds of people working on it,” Chalgren says. “We built Arena Exchange because if you have a supply chain with 20 suppliers, it’s too hard to manage adding them to your systems. Licensing costs can be a barrier, as well provisioning all of those people and maintaining their controls and privileges. This way, they can see the entire BOM and all of the redlines, and look at a snapshot of the enterprise application.”

The technological ability to automate the ECO process is established in a number of tools. Ideally the ECO tool should be linked or integrated with ERP, product data management, PLM and other systems. The solution has to be easy to use for employees. If you require them to leave the tools they’re used to working in so they can initiate document management, you will either create new inefficiencies or users won’t embrace the system.

Companies also have to accurately map their ECO processes to successfully automate them. “The biggest challenge getting customers to understand their own processes and being willing to aggressively adhere to the process,” Lamond says. “You really have to take the time to stop and document processes so you can enforce them and automate the workflows.”

ECOs are critical for implementing design changes. Automating the ECO process using an electronic solution (whether that is a PLM, document management or other type of system) can streamline reviews and approvals, ensure accurate implementation of changes, provide auditable documentation for compliance purposes — and most importantly — ensure a fast time to market for improved designs.

More Info

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Brian Albright is the editorial director of Digital Engineering. Contact him at de-editors@digitaleng.news.

Follow DE