Editor’s Pick: Industrial 3D Printing Lands on Desktop

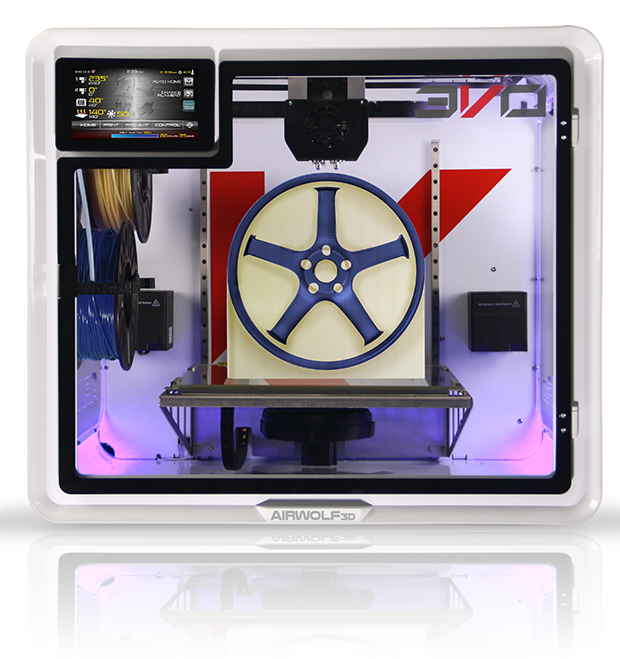

Airwolf 3D describes its new desktop-sized EVO Additive Manufacturing Center as offering technologies and user-centered design features that elevate the system to a new class of industrial equipment. Image courtesy of Airwolf 3D.

Latest News

January 31, 2018

Dear DE Reader:

Dear DE Reader:

Airwolf 3D makes interesting 3D printing equipment. They’re tough, affordable desktops with lots of versatile features, notably the ability to 3D print big parts with speed. Take its Axiom line. It has found its home in small and large engineering shops in various industries, as well as schools. From a link off today’s Editor’s Pick of the Week write-up, you can read and see how this outfit in San Diego uses them to make custom-fitted shoes.

Airwolf 3D recently took another step forward and introduced its fifth-generation additive manufacturing system. This unit, according to Airwolf 3D, brings industrial oomph to your desktop. It sounds pretty neat. And it’s not industrially priced—around $8K.

Airwolf 3D’s EVO Additive Manufacturing Center is its fifth-generation additive manufacturing system. The desktop-sized EVO supports 40 different materials and its large build volume can 3D print sizable parts. Image courtesy of Airwolf 3D.

Airwolf 3D’s EVO Additive Manufacturing Center is its fifth-generation additive manufacturing system. The desktop-sized EVO supports 40 different materials and its large build volume can 3D print sizable parts. Image courtesy of Airwolf 3D.Named the EVO Additive Manufacturing Center, this unit comes out of the box with a roomy 12x12x11-in. build volume and a snappy 250 mm-per-second print speed. It can print a 40-micron high layer, although Airwolf 3D recommends a 200-micron or better layer height.

The EVO sports dual printheads. It auto levels and calibrates. It has linear precision guides and an LED-lit machine vision system. A full-color touchscreen provides controls and status reports. A nice touch is that EVO has a HEPA and carbon filter air-purifying system that actively contains ultra-fine particles and volatile organic compound emissions.

EVO, which is a wordplay on EVOlution, will work with 40 different materials. That includes materials with print temperatures up to 320ºC (608ºF) as well as carbon-fiber-reinforced nylon and water-soluble materials. In practical terms, that high temperature flexibility means you can put EVO’s build volume to good use making large parts out of thermoplastics like ABS (acrylonitrile butadiene styrene) and polypropylene.

Good stuff. But EVO also introduces a pair of functions that were obviously developed with operator comfort in mind. First is PartSave. It’s your backup if the power fails. PartSave “remembers” what was going on and resumes printing the part right where EVO stopped after the power comes back.

FailSafe is the second creature feature. It’s your backup when, say, you space out and let the filament run out or something jams. It lets you reposition the printhead where things went awry and resume the job.

Speaking of space, I’m out of it. Hit today’s Editor’s Pick of the Week link to start learning about the EVO Additive Manufacturing Center. Well worth the time.

Thanks, Pal. – Lockwood

Anthony J. Lockwood

Editor at Large, DE

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Anthony J. Lockwood is Digital Engineering’s founding editor. He is now retired. Contact him via de-editors@digitaleng.news.

Follow DE